WTFrack.org - Sept 27, 2011

Weston Wilson, a former U.S. Environmental Protection Agency environmental engineer in Denver, asked Ramurthy if Halliburton uses radioactive tracer chemicals in its fracking fluids.

"Halliburton doesn't use radioactive tracers," Ramurthy said. "That's another company."

TracerScanSM Radioactive Tracer Log Service

Tracking Tracers Yields a Range of Formation Answers

The

With the TracerScan service, operators can simultaneously estimate natural gamma ray background for more reliable tracer data. Only one run is required after tracer placement because TracerScan service measures gamma ray spectra rather than tracer half-life. The technique also results in environmental benefits because tracers with a short half-life rapidly decay to environmentally safe levels.

For hydraulic fracturing operations, TracerScan service identifies fractured and propped intervals to determine if the tagged materials were pumped away from the wellbore as desired (see image). TracerScan™ logs monitor the effects of tagged acid jobs and allow the dissolution of the rock matrix. A relative distance calculation reveals the radial distribution of the cement and verifies that channels have been closed. The relative distance calculation also confirms placement of tagged packing materials in FracPac™ and gravel pack operations.

CLICK IMAGE TO ENLARGE

Following FracPac stimulation, wireline logs can be run to help evaluate treatment effectiveness. Logs can determine the height of hydraulically induced fractures, verify the placement of pack materials, and analyze flow from treated formations. Tracer and production logs are the wireline services most commonly used for FracPac evaluation.

VERIFYING PLACEMENT OF PUMPED MATERIALS

To verify the placement of pumped materials such as fracturing fluid, proppant, and gravel, spectral gamma ray tools such as Halliburton’s TracerScan tool are used. The materials to be pumped are tagged with radioactive tracers that have dissimilar gamma ray spectra. Each tracer emits gamma rays of different energies and different intensities than the other tracers. In a FracPac job, the fracturing fluid may be tagged with one tracer, the proppant with a second tracer, and the gravel with a third tracer. Since the TracerScan tool can distinguish gamma rays in different energy ranges, it can differentiate the tracers after they have been pumped downhole during FracPac operations.

TracerScan logs record spectral gamma ray data as a function of depth and therefore can evaluate the vertical distribution of the tagged materials. This allows the total and propped fracture heights to be estimated and voids in gravel packs to be located.

TracerScan logs record spectral gamma ray data as a function of depth and therefore can evaluate the vertical distribution of the tagged materials. This allows the total and propped fracture heights to be estimated and voids in gravel packs to be located.

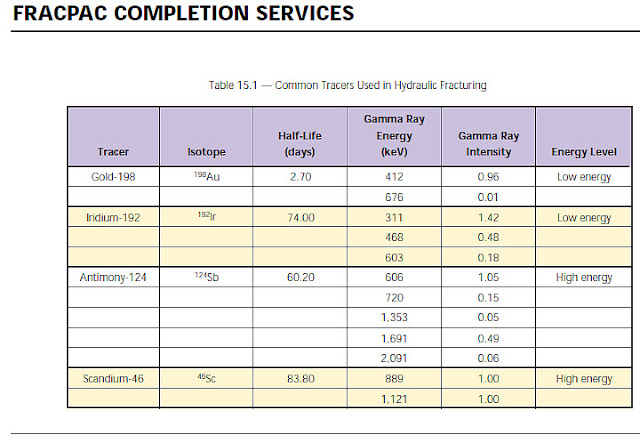

TracerScan data also give information regarding the approximate radial location of tracers and permits tracers in the borehole to be distinguished from tracers in the formation are at some distance from the wellbore, high-energy tracers (those with most gamma ray energies exceeding 600 keV) are more easily detected than are low-energy tracers. Thus, high-energy tracers, especially those with energies above 1,000 keV, are more suitable for tagging materials used during the early stages of fracturing operations. Table 15.1 gives energy levels and half-lives of several tracers used in evaluating fracturing and gravel packing operations.

TRACER SPECTRAL PEAKS – When more than one tracer is used, the gamma ray spectra of the tracers must be considered. The major gamma ray peaks in each spectrum must be sufficiently different from those in the other spectra so that the tracers can be easily distinguished from one another. One of these combinations is suitable for TracerScan work, and the other is not.

NUMBER OF TRACERS – In general, the minimum number of tracers should be used to evaluate the FracPac treatment. As the number of isotopes that are used increases, it becomes more difficult to spectrally differentiate the isotopes. It also becomes more difficult to determine precisely the concentrations and the radial-distance indicators.

TRACER HALF-LIVES – Tracer half-lives should be long enough so that if there are reasonable job delays, it should not be necessary to obtain additional tracers. Tracers with half-lives on the order of 60 days are commonly used, but specific jobs may require shorter or longer times.

TRACER TYPES – In 1992, TracerScan log interpretation was enhanced by the introduction of zero-wash tracers, also known as zero-leach tracers. Before zero-wash tracers became available, tracers were prone to wash off the tagged material or to plate out on tubular assemblies. This caused abnormally high tracer concentrations in the borehole. The new technology has eliminated the wash-off and plating tendency for solid tracers; however, except for scandium, liquid tracers still exhibit this characteristic. Nevertheless, liquid tracers can be used successfully, but it is critical that the tagging agent be chemically formulated so that preferential deposition of the tracer will occur in the formation and not in the borehole.

TRACER CONCENTRATIONS – There is a natural variation in the intensity of gamma rays emitted by tracers; thus, TracerScan measurements will exhibit statistical variations. Tracer concentrations on tagged materials must be high enough to minimize these statistical variations in TracerScan measurements but must be low enough to not distort tool response. Spectral gamma ray tools are designed for a linear response up to a certain maximum gamma counting rate (generally between 2,000 and 5,000 API units); higher rates degrade the response.

Tracer injection rates are commonly a few tenths of a millicurie per 1,000 gallons of fluid (a few megaBecquerels per cubic meter of fluid, or a few hundredths of a megaBecquerel per kilogram of solid). These rates usually result in gamma ray measurements ofa few hundred to a few thousand API units.

Tracer injection rates are commonly a few tenths of a millicurie per 1,000 gallons of fluid (a few megaBecquerels per cubic meter of fluid, or a few hundredths of a megaBecquerel per kilogram of solid). These rates usually result in gamma ray measurements ofa few hundred to a few thousand API units.

Since the gravel is concentrated in the borehole and the fracturing fluid and proppant are dispersed in the formation, care must be taken in selecting the tracers and their concentrations so that gamma rays from tracers in the formation are not obscured by gamma rays from tracers in the borehole. It is also important that the tagged components of the FracPac job be pumped in a manner that is representative of the FracPac operation as a whole.

CLICK IMAGE TO ENLARGE

Data Quality Considerations

Several measures can be taken to ensure that the information obtained from TracerScan logs is of the highest quality possible. In general, these measures increase the accuracy of measured data and reduce the number of interpretation possibilities. First, information from other logs, especially gamma ray and sonic, is helpful. Although not required, a TracerScan log can be run before a FracPac job to measure the background gamma radiation that must be subtracted from the later tracer measurements.

When such a prejob TracerScan log is not run, the background gamma ray is estimated from the post job log.

---------------------------------------------------------------------

No comments:

Post a Comment

WTFrack.org is a medium for concerned citizens to express their opinions in regards to 'Fracking.' We are Representatives of Democracy. We are Fractivists. We are you.